Without optimization to quickly consider all 12 designs, the changes made to the tooling would not have been possible in this case. To run samples in production to test all 12 versions would have taken weeks, with material and labor costs that could not have been justified. The calculation of these 12 versions was done on an 8-core workstation and took 22.5 hours. Thanks to the positive results, it was possible to reduce both the amount of magnetic particle inspections required as well as the amount of re-work time. In this case, the riser changes resulted in a 30% reduction of strain during solidification, while the modified casting design reduced the strain during solidification by 44%. The assessment tools in MAGMASOFT® allowed for a quantitative determination of how each design variable impacts each of the objectives. For this purpose, the position of the casting, the casting geometry, the feeder configuration and the process parameters were modified.īy adopting this solution, it was possible to reduce the stresses and the plastic deformations in the critical solidification range by 61% compared to the original situation. The corresponding quality criteria for feeding and the susceptibility to hot tearing were autonomously evaluated in the critical areas.Ī total of 12 different solutions were developed and analyzed.

Methoding magmasoft crack#

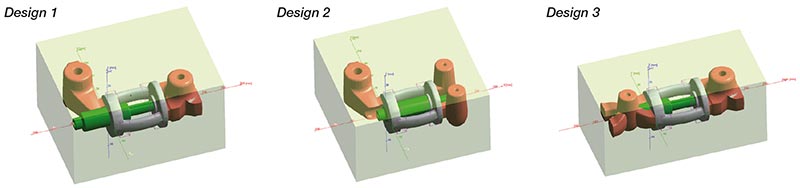

In doing so, the solidification and cooling of the part to ambient temperature, including the resulting stresses and crack susceptibility, were analyzed for each combination of the different casting designs and riser configurations. To achieve these objectives, both the part geometry and the feeding system were varied and autonomously exchanged in a design of experiments (DoE) in MAGMASOFT®.

Methoding magmasoft software#

The following tasks were assigned to the software as objectives: first, hot tears in the problem area should be prevented secondly, the necessary changes should not decrease the soundness of the part by creating shrinkage porosity defects.

To tackle this task in a timely and cost-efficient manner, they began examining different variants using the capabilities of autonomous optimization in the newest version of MAGMASOFT®. Eagle Alloy concluded that in order to optimize production, it was necessary to work out and verify changes both in the casting design and in the gating and risering.

0 kommentar(er)

0 kommentar(er)